News Center

Dynamic Company

Contact Us

Suzhou ExGooD Intelligent Equipment Co., Ltd

Contact person: Manager Zhang

Tel: 152-6249-2881

159-6256-6959

Email: salzj@egdmac.com

salzs@egdmac.com

Address: No.555, xugongqiao Road, Huaqiao Town, Kunshan City, Jiangsu Province

News Center

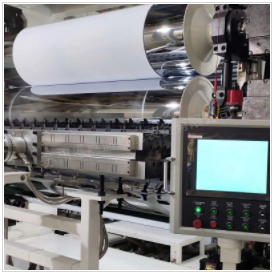

Drying temperature and time of PET sheet extrusion equipment?

Release Date:2021-01-19 Content Comes From:http://hxx7p.cn/en/

Drying temperature and time of PET sheet extrusion equipment?

Pet (scientific name: polyethylene terephthalate) is also called polyester in Chinese. It has excellent gas barrier, pressure resistance, impact resistance, transparency and surface gloss. It has been widely used in food containers because of its odorless and fragrance retention, safety in food hygiene, beautiful appearance and easy molding.

Pet is crystalline resin, the specific gravity is about 1.4kg/l, the melting point is 245 ℃, and the molding temperature is about 290 ~ 315 ℃. The bulk density of particles ranged from 0.8 to 0.85 kg / L, and that of sheet ranged from 0.38 to 0.4 kg / L.

Pet is mainly used in the fields of synthetic fiber, PET bottle and film sheet. In recent years, with the development of economy, people's awareness of environmental protection has been enhanced. As a kind of packaging material, PET sheet shows good development potential in replacing difficult to recycle PVC packaging material.

Pet is crystalline resin, the specific gravity is about 1.4kg/l, the melting point is 245 ℃, and the molding temperature is about 290 ~ 315 ℃. The bulk density of particles ranged from 0.8 to 0.85 kg / L, and that of sheet ranged from 0.38 to 0.4 kg / L.

Pet is mainly used in the fields of synthetic fiber, PET bottle and film sheet. In recent years, with the development of economy, people's awareness of environmental protection has been enhanced. As a kind of packaging material, PET sheet shows good development potential in replacing difficult to recycle PVC packaging material. Because of the strong hygroscopicity of pet, the drying treatment before processing is necessary. The recommended drying condition is 120 ~ 165 ℃ for 4 ~ 6 hours. For sheet extrusion line, the moisture content after drying should be less than 200ppm; for bottle embryo production line, the moisture content after drying should be less than 50ppm; for conventional spinning, the moisture content should be less than 50ppm; for high speed spinning, the moisture content should be less than 35ppm.

temperature

In general, the higher the drying temperature, the higher the drying rate; the shorter the drying time, the lower the moisture content of raw materials. The drying temperature of stirring mould is usually between 120 ℃ and 160 ℃. The dehumidification drying temperature is 160 ~ 180 ℃.

time

The crystallization time is 1 ~ 2 hours, and the crystallization time is inversely proportional to the pre crystallization temperature.

The drying time is 4 ~ 6 hours to make the moisture content of pet close to or reach the equilibrium moisture content; the drying time is related to the drying temperature, vacuum degree and dry air moisture content.

Related Tags: Sheet extrusion equipment

| Critics: | |

| Contacs: | |

| Marked Contents: | |

| Code | |