News Center

Dynamic Company

Contact Us

Suzhou ExGooD Intelligent Equipment Co., Ltd

Contact person: Manager Zhang

Tel: 152-6249-2881

159-6256-6959

Email: salzj@egdmac.com

salzs@egdmac.com

Address: No.555, xugongqiao Road, Huaqiao Town, Kunshan City, Jiangsu Province

News Center

Extruder is one of the important parts of PVC pipe production line

Release Date:2021-01-19 Content Comes From:http://hxx7p.cn/en/

What are the important parts of PVC pipe equipment? Professional sheet extrusion equipment manufacturer, enjiadi, will take you to know the important part of PVC pipe equipment!

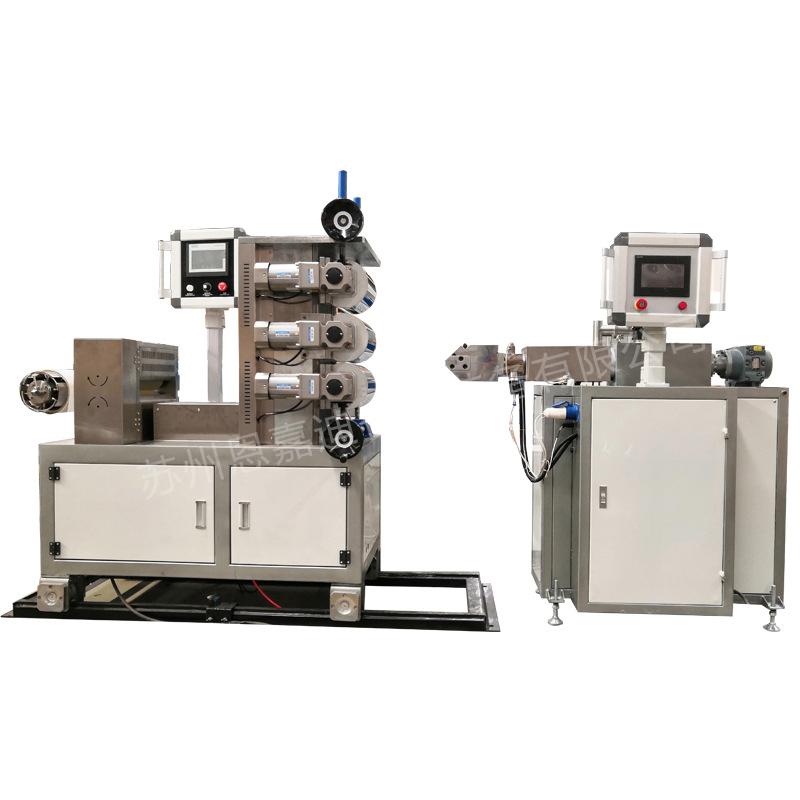

① Extruder part

The machine is equipped with a quantitative feeding device, so that the extrusion amount and feeding amount match to ensure the stable extrusion of products. Because of the use of conical twin-screw, the feeding section has a larger diameter, so the heat transfer area and shear speed of the material are larger, which is conducive to the plasticization of the material. The diameter of the screw in the metering section is smaller, which reduces the heat transfer area and shear speed of the melt, so that the melt can be extruded at a lower temperature. When the screw rotates in the barrel, the PVC mixture is plasticized and pushed to the head, so as to achieve compaction, melting, mixing homogenization, and realize the purpose of exhaust and dehydration. The feeding device and screw drive device adopt frequency conversion speed regulation, which can realize synchronous speed regulation.

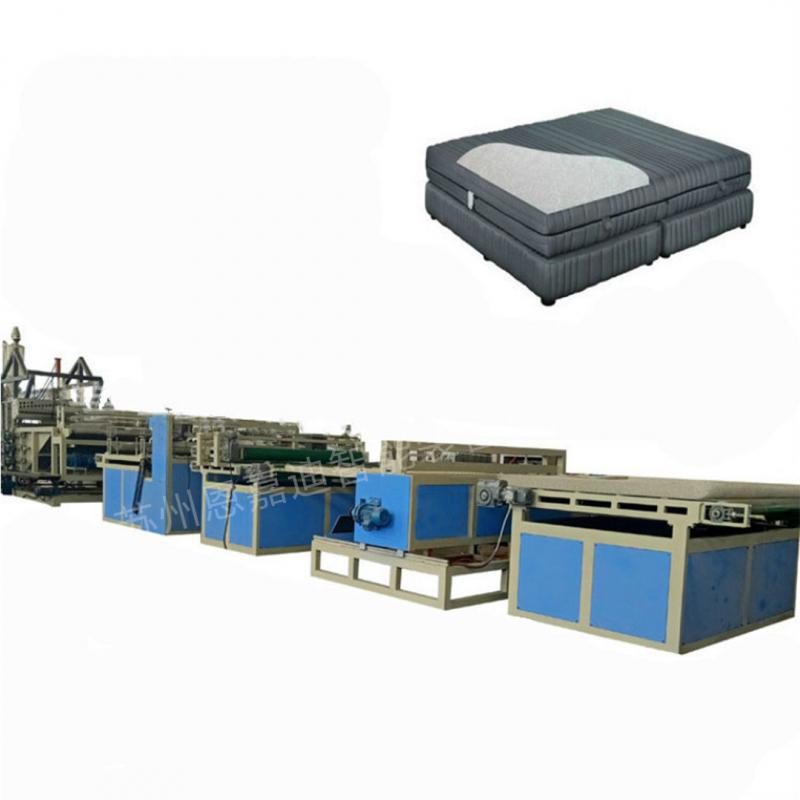

② Die head part: PVC after compaction, melting, mixing and homogenization, with follow-up materials pushed to die head by screw, and extrusion die head is the key component of pipe forming.

③ Vacuum sizing water tank part: vacuum sizing is an important core part of all pipe equipment, which is conducive to high-speed extrusion of pipes.

④ Traction machine part: frequency conversion speed regulation is used to continuously and automatically lead the cooled and hardened pipes out of the machine head, which saves energy and is stable and durable.

⑤ Cutting machine part: after the stroke switch is controlled according to the required length, the automatic cutting is carried out, and the frame turnover is delayed to implement flow production. The cutting machine takes the fixed length switch signal as the command to complete the whole cutting process, which keeps synchronous with the pipe operation in the cutting process. The cutting process is completed by electric and pneumatic drive, The cutting machine is equipped with a dust suction device to suck out and recycle the debris produced by cutting in time.

⑥ Turning frame part: the turning action is controlled by the air cylinder through the air circuit, and the turning is equipped with a limit device. When the pipe is cut by the cutting saw, the pipe continues to be transported. After the delay, the air cylinder enters the work to realize the turning action and achieve the unloading purpose. After unloading, it will reset automatically after several seconds delay, waiting for the next cycle.

Through the introduction of engardi, a professional sheet extrusion equipment manufacturer, you must have a preliminary understanding of the important components of PVC pipe equipment. If you want to know more about sheet extrusion production equipment details and other information, you can follow our website, contact our customer service, welcome to inquire!