News Center

Dynamic Company

Contact Us

Suzhou ExGooD Intelligent Equipment Co., Ltd

Contact person: Manager Zhang

Tel: 152-6249-2881

159-6256-6959

Email: salzj@egdmac.com

salzs@egdmac.com

Address: No.555, xugongqiao Road, Huaqiao Town, Kunshan City, Jiangsu Province

News Center

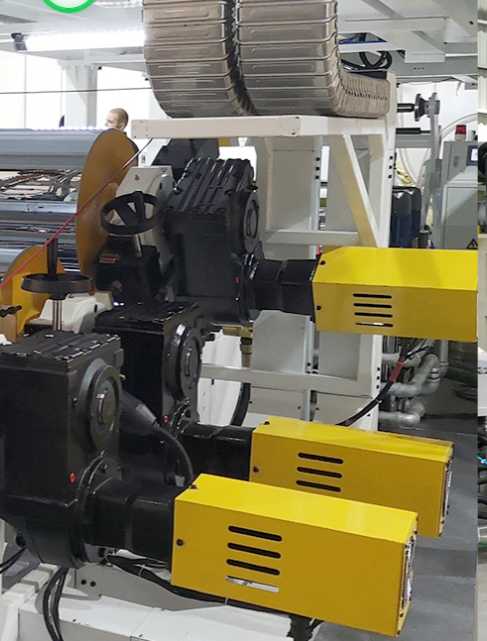

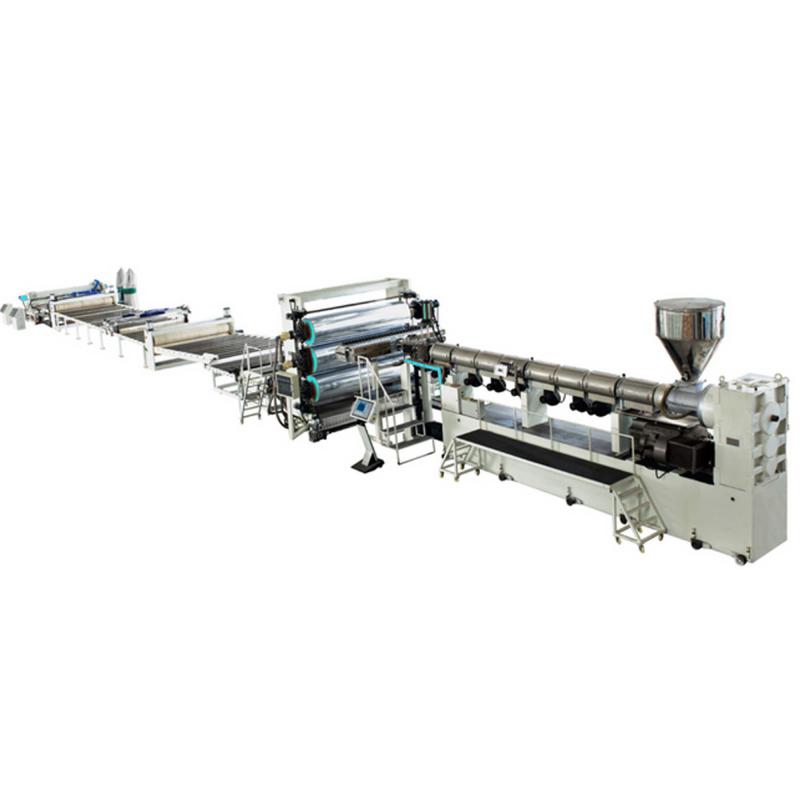

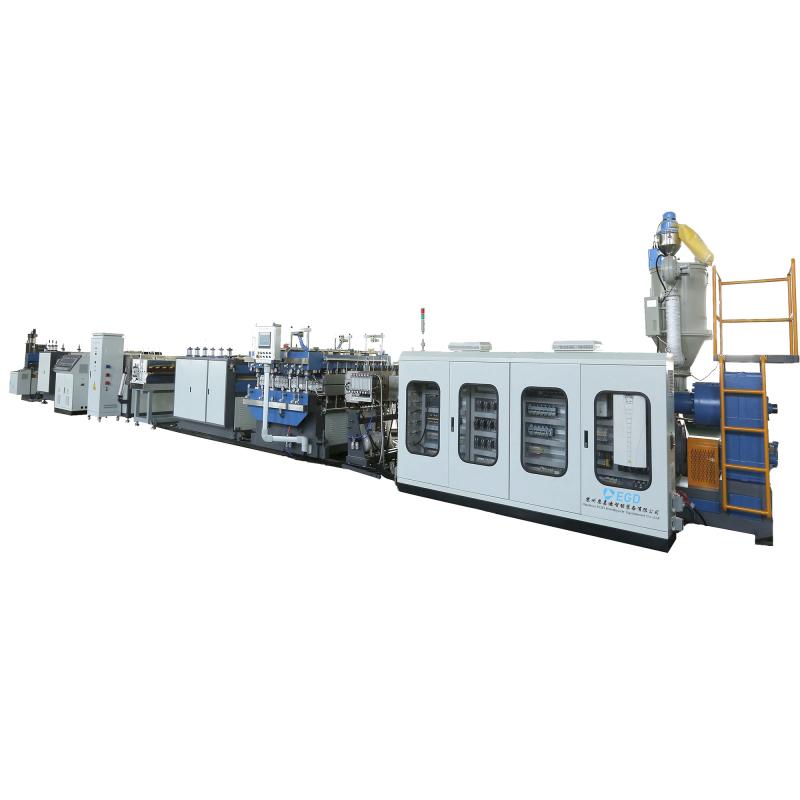

Multi layer co extrusion PET sheet production line

Release Date:2021-01-19 Content Comes From:http://hxx7p.cn/en/

Multi layer co extrusion PET sheet production line. Extruders for PET sheet production can be divided into continuous extrusion and non continuous extrusion according to their function types. Plastic extruder is also a kind of plastic machinery. According to the angle between the material flow direction of the head and the center line of the screw, the head of the extruder is divided into oblique head (angle 120 ο) and right angle head. The shell of the machine head is fixed on the machine body with bolts. The mold in the machine head has a mold core seat, which is fixed on the wire inlet port of the machine head with nuts. The front of the mold core seat is equipped with a mold core, and there are holes in the center of the mold core and the mold core seat for passing through the core wire.

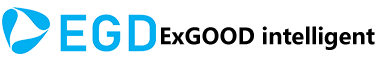

A multi-layer co extrusion PET sheet production line is mainly composed of a plastic extruder, a lamination machine, an extrusion die head, a three roller tablet press, a cooling trimming machine, a traction machine and a sheet winding machine. The plastic extruder adopts a twin-screw extrusion structure; the surfaces of the two screws in the plastic extruder are polished surfaces after nitriding treatment; and The utility model comprises an extruding cylinder, the inner surface of the extruding cylinder is a polished surface after nitriding treatment; the extruding cylinder is provided with a cast aluminum heating ring, and the periphery of the cast aluminum heating ring is provided with a stainless steel heating cover; one side of the extruding cylinder is provided with a thermostatic controller, and the thermostatic controller adopts a RKC temperature controller produced by Japan to control the temperature in the extruding cylinder; the plastic extruder is also provided with a heating cover Four sets of pressure display and sensing devices. The beneficial effect of the utility model is that the PET sheet produced by the above production line has stable performance and good quality, and the waste can be recycled, and no residue and toxic gas will be left after incineration, which is conducive to environmental protection; compared with other domestic machines, the utility model has the advantages of high efficiency, low energy consumption, complete functions and simple operation advantage.