News Center

Dynamic Company

Contact Us

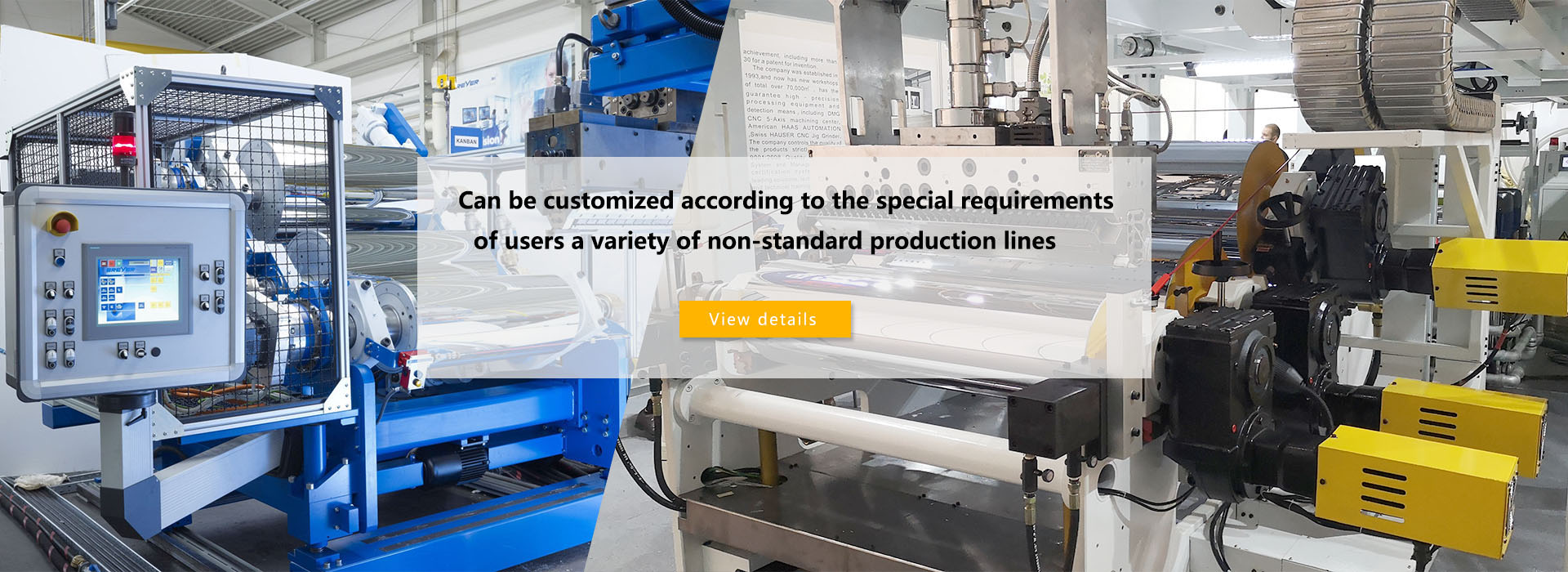

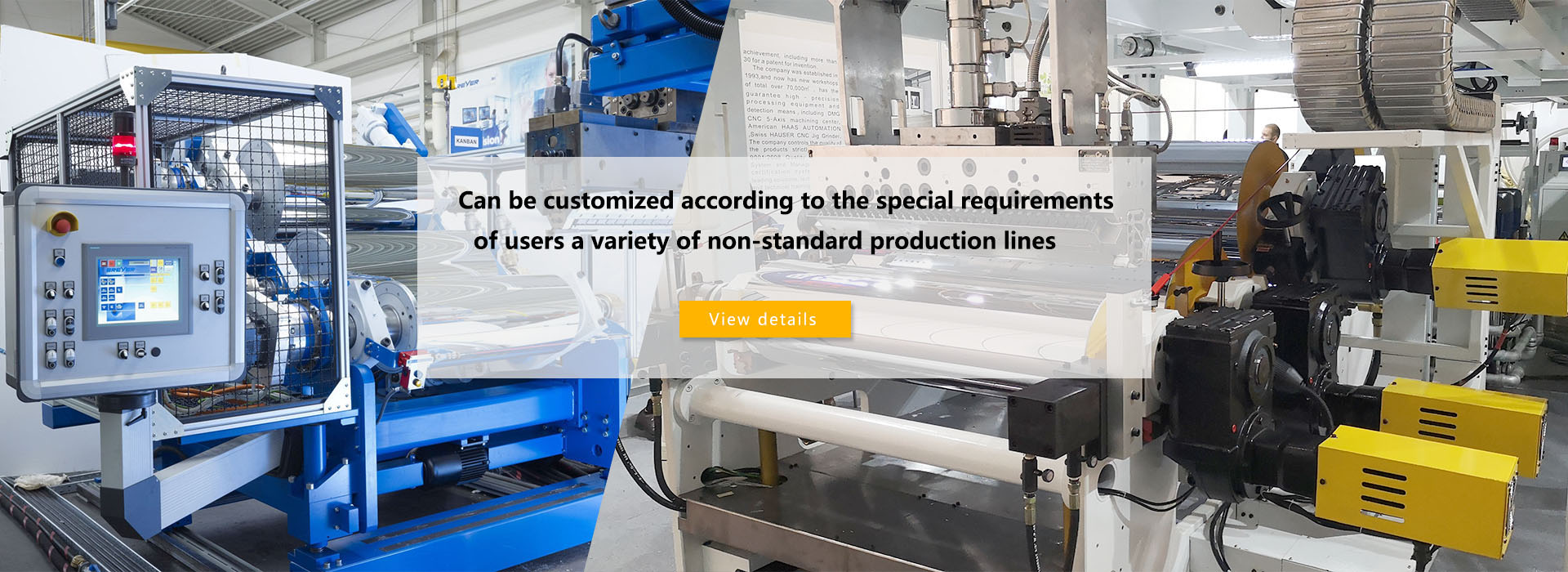

Suzhou ExGooD Intelligent Equipment Co., Ltd

Contact person: Manager Zhang

Tel: 152-6249-2881

159-6256-6959

Email: salzj@egdmac.com

salzs@egdmac.com

Address: No.555, xugongqiao Road, Huaqiao Town, Kunshan City, Jiangsu Province

News Center

What are the main and auxiliary drives of pet packing belt equipment?

Release Date:2021-01-19 Content Comes From:http://hxx7p.cn/en/

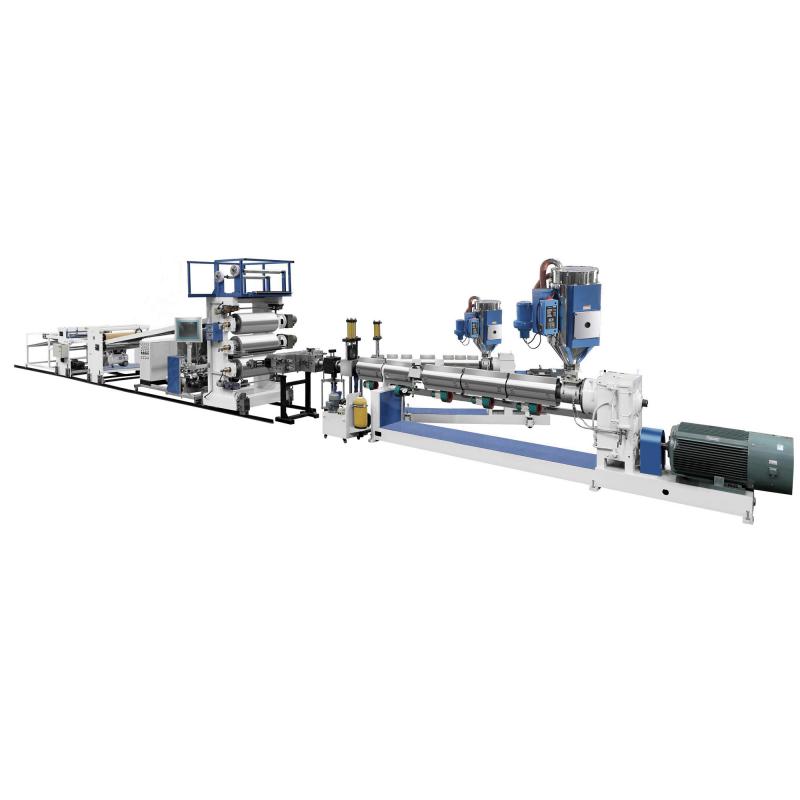

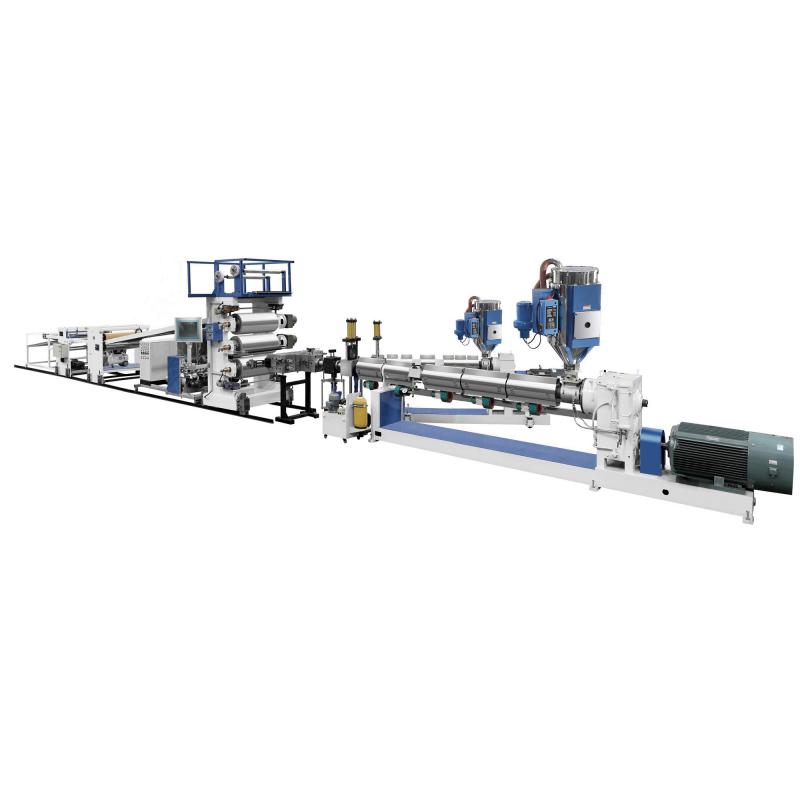

What are the main and auxiliary drives of pet packing belt equipment? Enjiadi, a manufacturer of ABS plate production line for high performance plastic plate and sheet extrusion equipment, introduces to you:

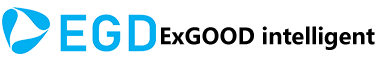

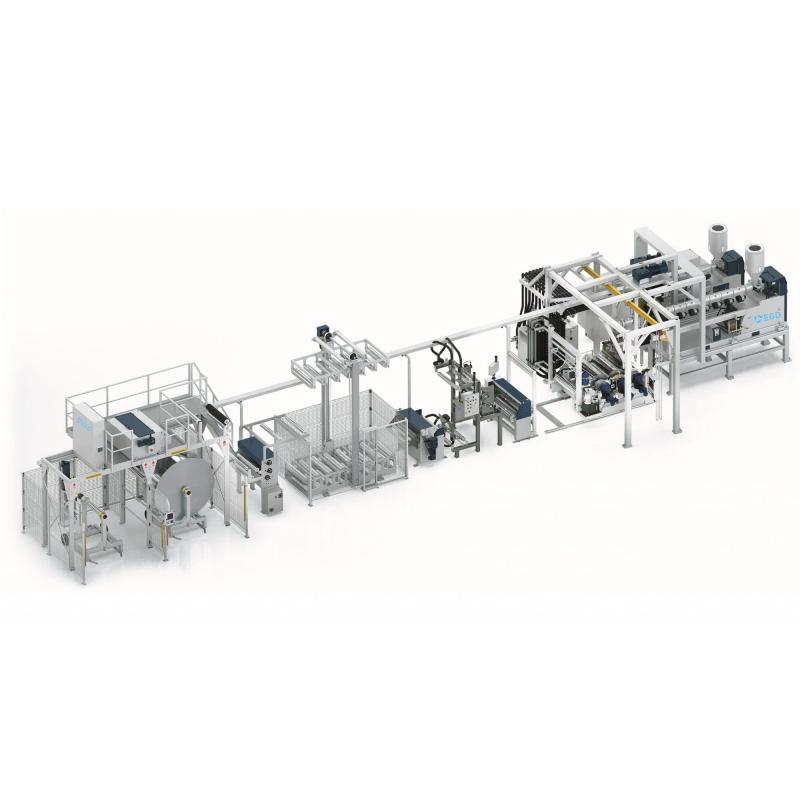

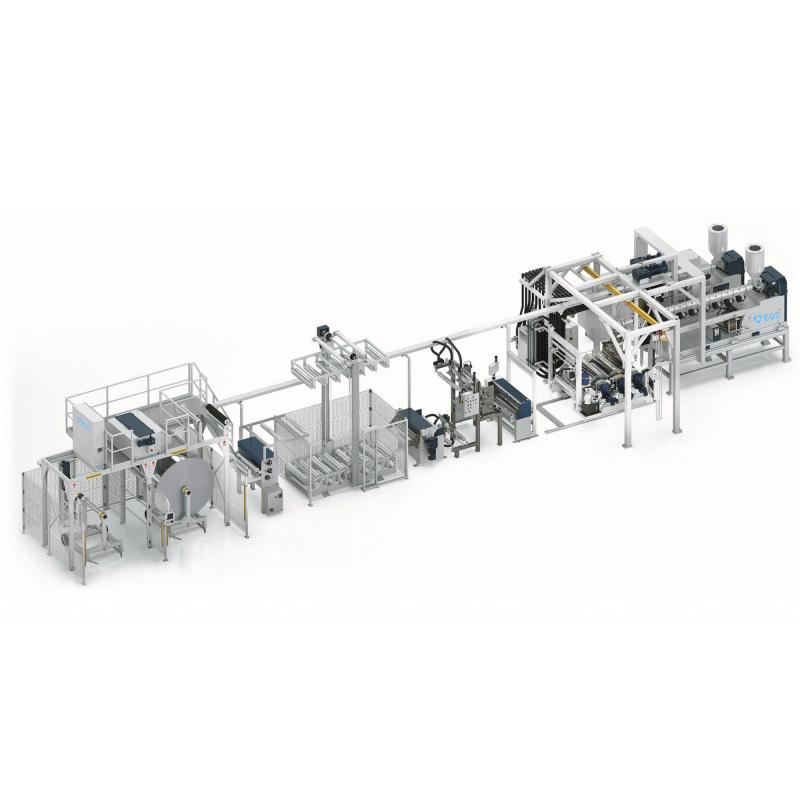

First of all, we follow the sheet extrusion equipment ABS plate production line manufacturers to understand the next PET packaging equipment. Pet packing belt equipment is a series of mechanical equipment for producing packing belt. Pet packing belt equipment is mainly composed of automatic feeder, dryer (or dehumidification drying device), extruder, filter, mold, water tank, tractor, oven, stretching unit, heat setting box, winding machine, etc.

Next, the sheet extrusion equipment ABS plate production line manufacturers introduce the working principle of pet packing belt equipment, as follows:

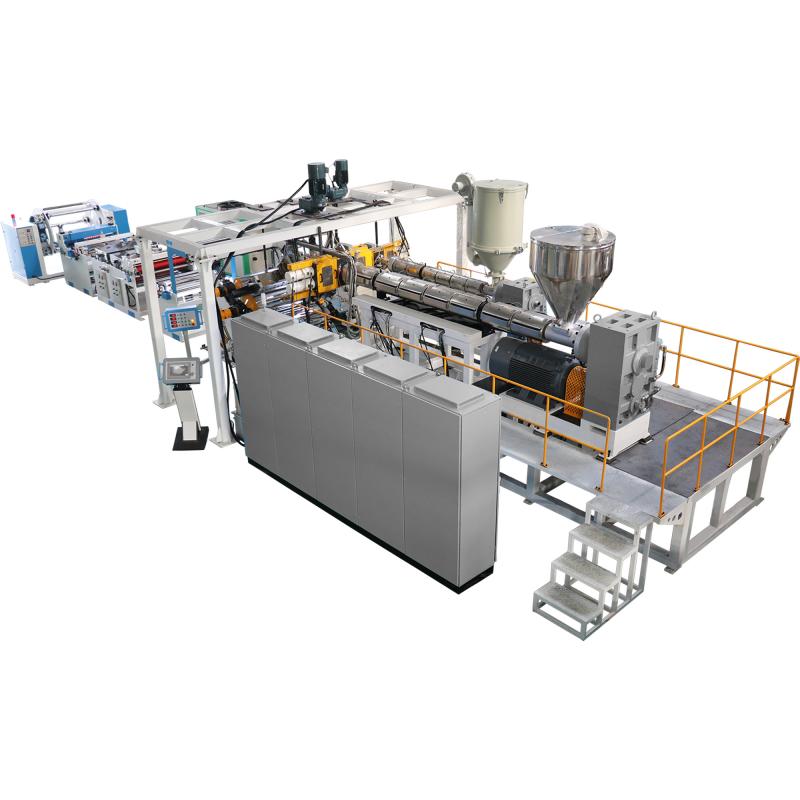

1. The main and auxiliary drive of pet packing belt equipment is composed of speed regulating motor, reducer and shaft sleeve. The forming part is composed of screw barrel, head and die. The raw material is heated and extruded from the hopper to the screw barrel. The first section of the temperature control fuselage is 120 degrees, the second section is 170 degrees, the third section is 220 degrees, and the nose is 250-280 degrees.

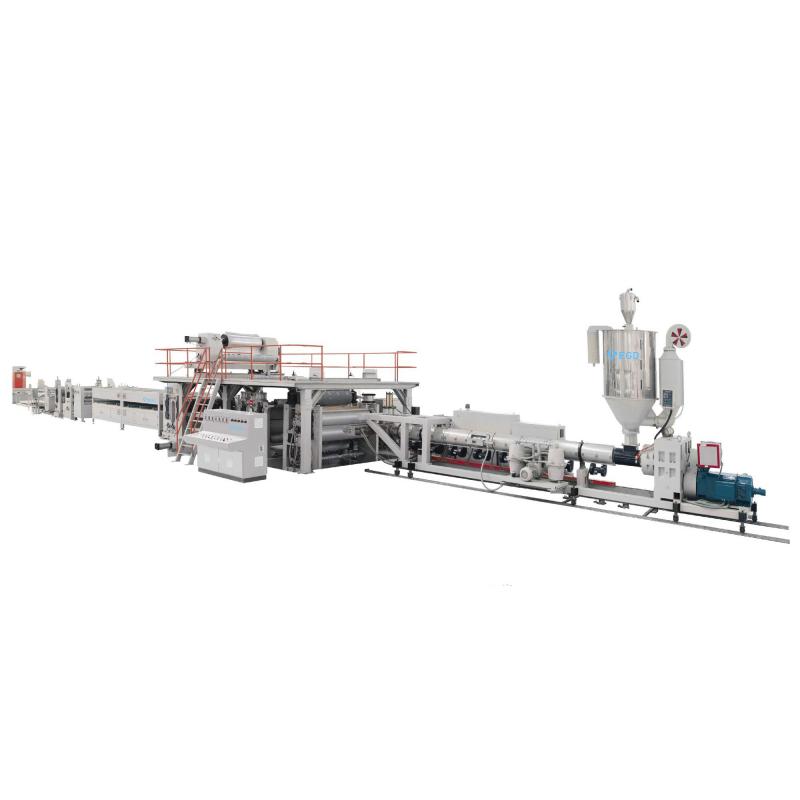

2. The lower water tank of pet packing belt equipment cools and sets the primary embryo of main and auxiliary die. The temperature of the strip is very high after it is discharged from the die, so it should be cooled in water immediately, because the crystal structure of isotactic polypropylene is easy to form in the case of rapid cooling, and the crystal molecular structure is loose. It is easy to stretch and get high quality products. (warm reminder: the cooling water temperature of the packing belt production line is generally controlled at 30-40 degrees, and the distance between the die mouth of the packing belt production line and the water surface is 15-45mm).

3. The first traction of pet packing belt equipment is composed of speed regulating motor, traction roller, reducer and chain drive. It transports the shaped embryo to the oven.

4. The main purpose of stretching is to improve the longitudinal strength of the packaging belt and reduce the elongation. Three times heating in the oven of the packaging belt production line can eliminate the tensile stress, and the upper water tank can eliminate the thermal stress before setting.

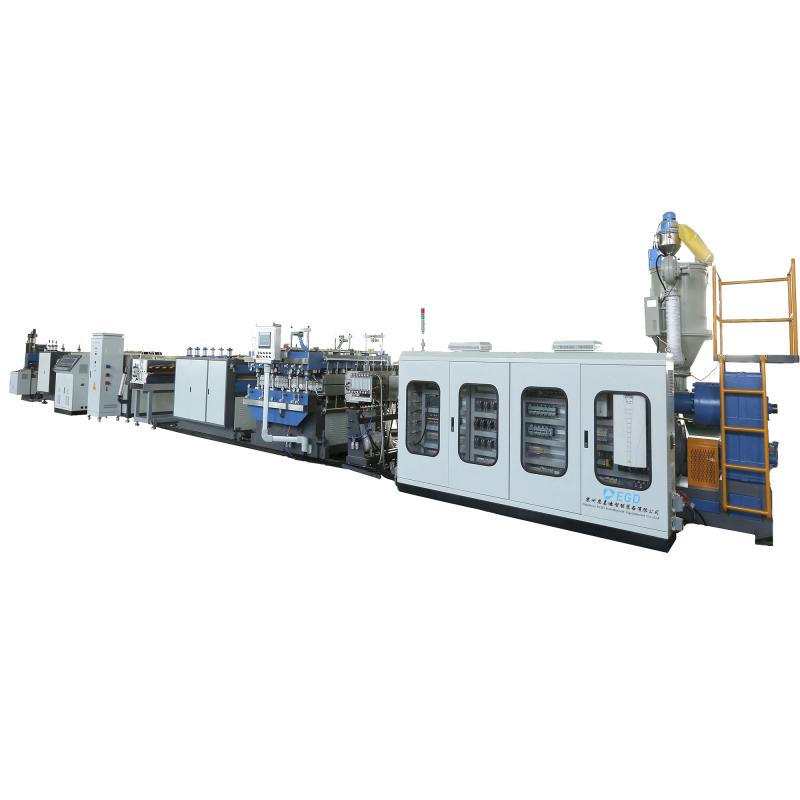

5. The drive of embossing machine for pet packing belt equipment is speed regulating motor, which is driven to the second traction, embossing and traction through belt drive, chain drive and gear drive. The second traction is to stretch the secondary heated primary embryo through the pull bar again, and then transfer it to the embossing roller; the stretched packing belt will be pressed with patterns after passing through two patterned rollers, and its function is to increase friction in use, without slipping, and it is beautiful from the appearance. The product surface is embossed by the embossing roller and then transported to the upper water tank or the upper oven; the packing belt production line transports the forming of the upper water tank to the coiler through the third traction.

6. The drive of the coiler of PET packaging belt equipment is that the speed regulating motor transmits to the coiler shaft and stroke rod respectively through belt drive and chain drive. It is to roll up the qualified product into a single product with specified shape and quality.